Pelton Hydro Turbine Repair

Turning - Milling - Threading - Tapping - Issue Resolution & Improvement

Due to catastrophic failure of the main shaft bearings the turbine continued to run, which resulted in wearing the housing and shaft, which caused failure of the shaft. The turbine was dismantled and inspected to evaluate the work required. This highlighted a number of failure paths including, worn seals into the shaft resulting in water flooding the bearings, worn shaft bearing journals causing vibrations and the pelton wheel had interfered with the houses causing it to be unbalanced.

We dismantled onsite and machined replacement parts including, shaft, bearing housing and main casting. To avoid subsequent repeat failure, we enhanced the original design. Example being installing greaseable back to back seals to avoid shaft wear and ensure seals have additional safety factors. The shaft was also upgraded to a duplex stainless steel to reduce shaft wear.

The completion of this work included on-site fitment and testing to ensure the turbine was restored to full functionality for power generation.

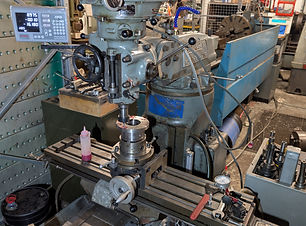

Initial machining of the casting to enable machining out the worn section for insertion of bearing housing

Counterboring the bearing housing.

Measuring of the machine casting, prior to the manufacturing of the new components.

New components ready for reassembly.

Selection of material for the new component manufacture.